The X-ray for Your Value Streams

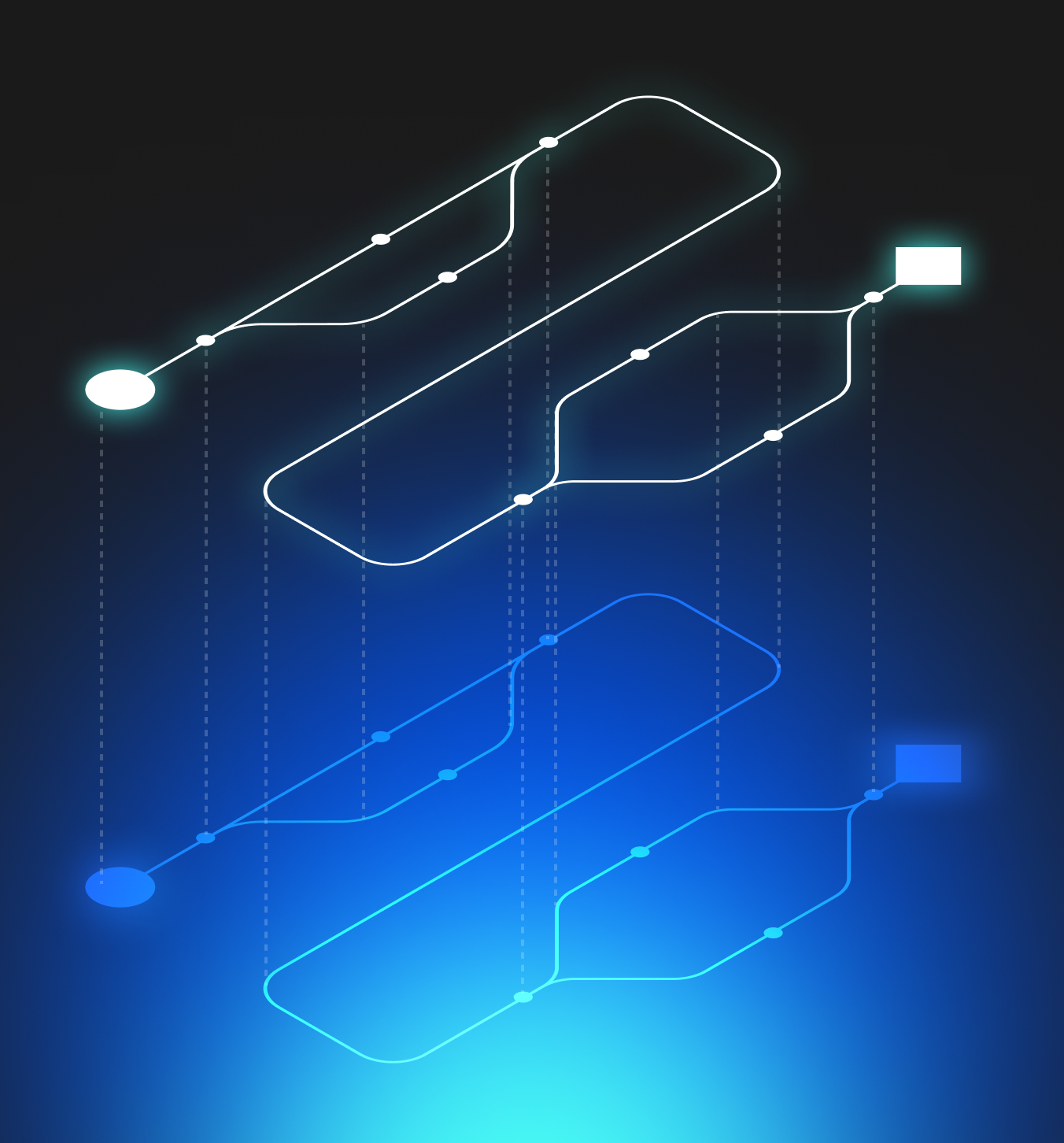

IQA reveals and x-rays the actual value streams at the touch of a button - for automated and continuous value stream analysis.

IQA reveals and x-rays the actual value streams at the touch of a button - for automated and continuous value stream analysis.

Value stream analysis is a proven method for process optimization, yet it has its limitations: high manual effort and a focus on isolated analyses of individual value streams and time frames make it both labor-intensive and limited in scope. Automated, data-driven analysis with IQA provides the solution.

From existing data in production-related IT systems, such as MES, PDA, or ERP, IQA automatically creates a digital twin of the actual production processes. This allows for end-to-end mapping and analysis of all value streams, making manual process mapping obsolete.

IQA provides the analyses and visualizations to quickly identify the most crucial areas of action at a glance – and then to analyze the value streams in depth. With the integrated Lean Analytics, even hidden inefficiencies and their causes become visible at the push of a button.

IQA automatically captures value streams based on existing data, eliminating the need for manual mapping. All relevant process information, such as times, quantities, scrap, and resource consumption, is integrated into the digital value stream twin and visualized through intuitive process graphs.

IQA visualizes and analyzes complex, multi-stage production processes in the Value Stream Twin. It holistically considers all involved value streams contributing to the manufacturing of a final product, linking them through the product's bill of materials. This creates a comprehensive view of the entire value creation chain for each product.

With IQA, a continuous, data-driven analysis of the value stream processes is enabled. Rather than relying on snapshots, value streams can be observed in real-time, historical value streams can be retraced, or analyzed over extended periods to gain statistically robust insights.

IQA illustrates logistics movements, inventory levels, and storage times within the production chain. The visualizations in the digital twin provide full transparency over material flow. Storage logics make lead times and movements across multiple manufacturing and assembly stages comprehensible.

IQA automatically generates the relevant production KPIs for each product without the need for additional configuration. Whether it's occupancy rate, WIP, OEE, scrap rate, or CO2 footprint – all KPIs are instantly available and can be conveniently visualized through dashboards, analytical charts, or directly within the process graph.

Through automated data analysis, implausible booking data can be swiftly detected and excluded from analyses, enabling data-driven process analysis even with flawed source data. Additionally, the quality of the data can be specifically examined and analyzed.

IQA provides automated analyses to detect waste in production processes and prioritize resulting action areas. Weaknesses are automatically identified and traced back to their root causes through AI-powered techniques.

IQA enables the rapid and data-driven identification of untapped productivity opportunities, along with the continuous monitoring of manufacturing KPIs. This effectively supports both daily shop floor management and continuous improvement process (CIP) through data-centric approaches.

IQA integrates the concepts of "lean" and "green": By analyzing the energy and CO2 footprint within the value stream, measures for enhancing efficiency and sustainability can be harmonized, resulting in holistic and comprehensive improvements.