Manufacturing performance requires more than just metrics - IQA empowers a new level of efficiency based on the intelligent twin of production processes.

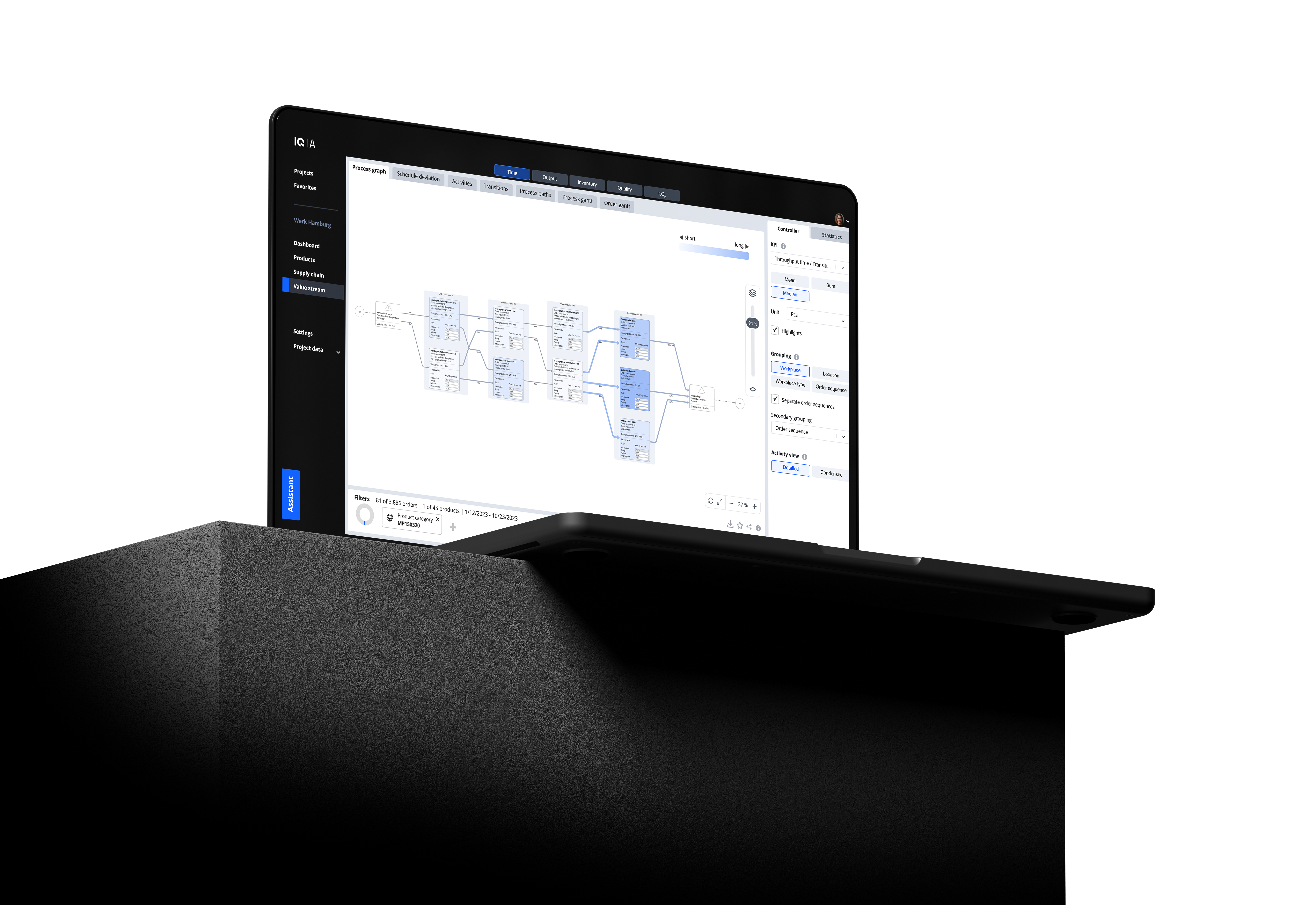

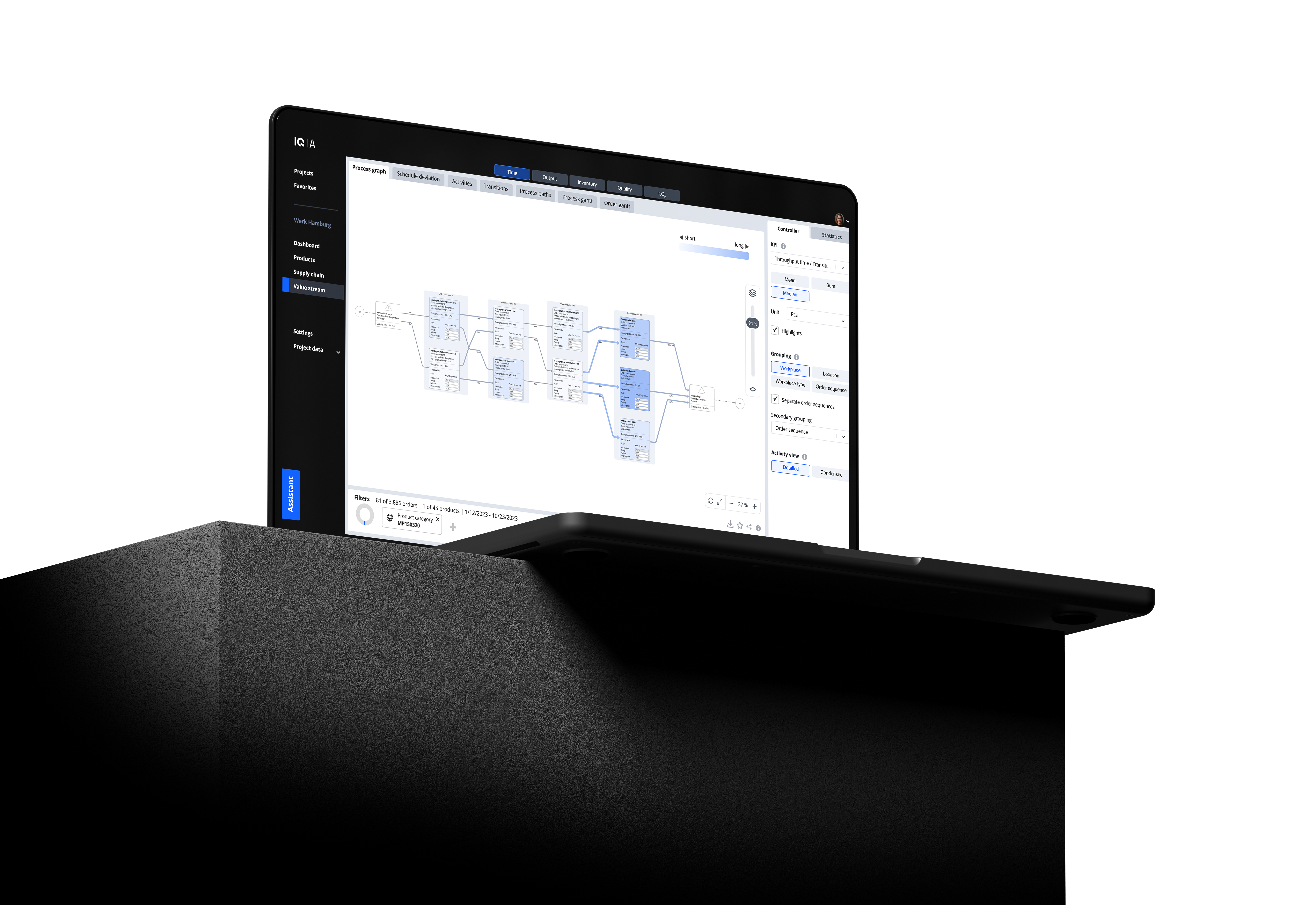

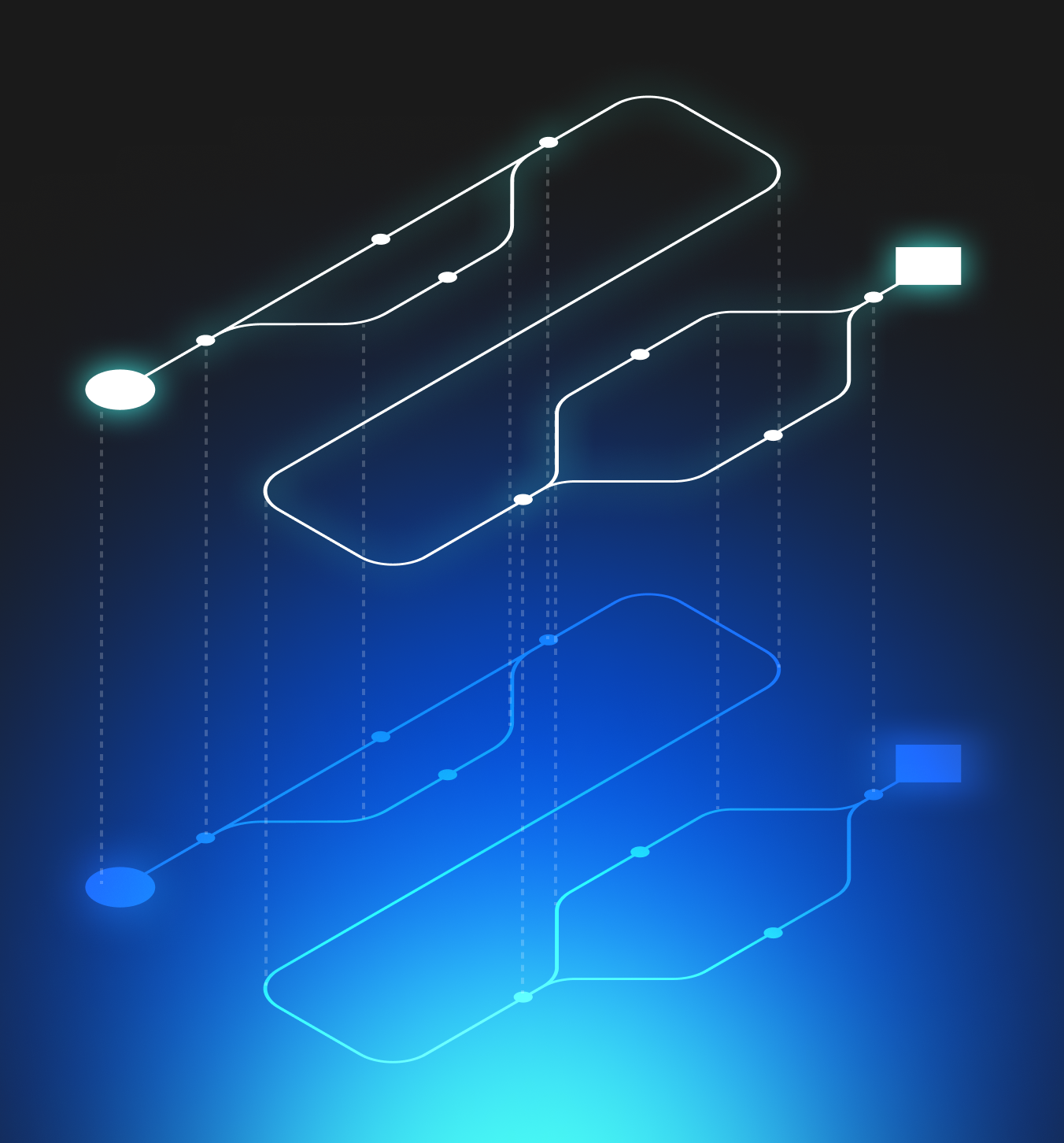

IQA automatically generates a digital twin of the actual production processes. Through intelligent analyses, it uncovers weaknesses and spots improvement potentials within the value streams, prioritizing action areas for immediate enhancement.

IQA utilizes Industrial Process Mining, specifically designed for Manufacturing, to automatically unveil the real production processes within a digital value stream twin. The software leverages existing data from production management or monitoring IT systems, transforming them into a digital representation of the actual value streams.

The value stream twin offers profound insights into production processes in significantly less time than conventional methods. IQA provides predefined Lean analyses that autonomously detect weaknesses in the value streams and highlight areas for improvement.

Leveraging Machine Learning, root cause analyses tailored for manufacturing identify complex correlations and drastically cut down the time needed for causality investigation. These analyses are immediately deployable, requiring no configuration or specialized AI knowledge.

Value streams for all products are automatically reconstructed from existing data. Instead of a labor-intensive, manual snapshot, all production and logistics processes are continuously captured in the digital twin and are analyzable on a broad data foundation.

IQA provides automated Lean analyses to detect waste in production processes and prioritize resulting action areas. Weaknesses are automatically identified and traced back to their root causes through AI-powered techniques.

IQA enables the rapid and data-driven identification of untapped productivity opportunities, along with the continuous monitoring of manufacturing KPIs. This effectively supports both daily shop floor management and continuous improvement process (CIP) through data-centric approaches.

IQA integrates the concepts of "lean" and "green": By analyzing the energy and CO2 footprint within the value stream, measures for enhancing efficiency and sustainability can be harmonized, resulting in holistic and comprehensive improvements.

IQA creates a digital value stream twin from booking and planning data sourced from production-related IT systems, such as MES, BDE, or PPS/APS, without the need for manual value stream mapping. All process KPIs, including times, production outputs, inventory levels (WIP), scrap, emissions, and more, are automatically determined and integrated into the value stream.

Value stream visualizations and AI-guided analyses tailored for manufacturing are already integrated, enabling easy and immediate deployment by your team. There's no requirement for configuration or extensive expertise in AI and data mining.

Order and material flows are captured and analyzed at the push of a button, even in multi-stage and interconnected value streams. IQA utilizes Industrial Process Mining techniques specifically designed for production processes, along with machine learning algorithms, to provide in-depth insights into complex processes.

Through automatic data analysis, implausible booking data can be swiftly detected and excluded from analyses, enabling data-driven process analysis even with flawed source data. Additionally, the quality of the data can be specifically examined and analyzed.

IQA is a lightweight, cloud-based extension of your existing IT systems. Implementation typically takes only a few days and requires no additional infrastructure.